Case Study: Robotic Welding for a Metal Stamped Part

Customer

Motorcycle Manufacturer

Part

Footboards

Manufacturing Issues

- The increasing variability when welding the hinges onto the footboards was risking the functionality and quality of the part.

- Manufacturing costs were growing to an unacceptable level as production quantities continued to increase.

Manufacturing Solution

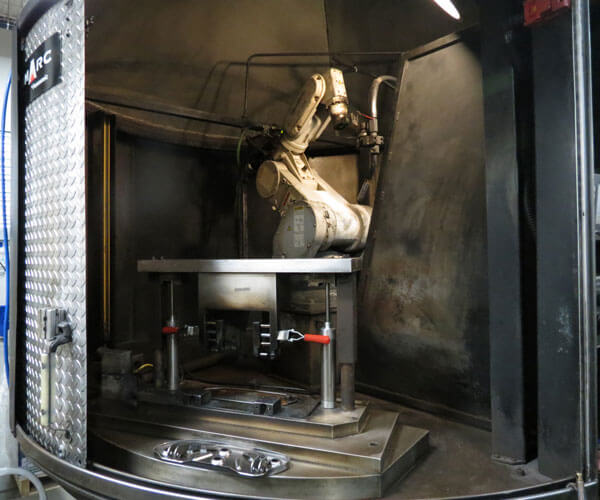

Robotic welding delivered consistent, high-precision welds while meeting the manufacturer’s increasing production demands. Unlike manual welding, the robotic arm operates with exact repeatability, eliminating human variability. Once programmed, it maintains a steady weld pace that improves quality and significantly increases production output.

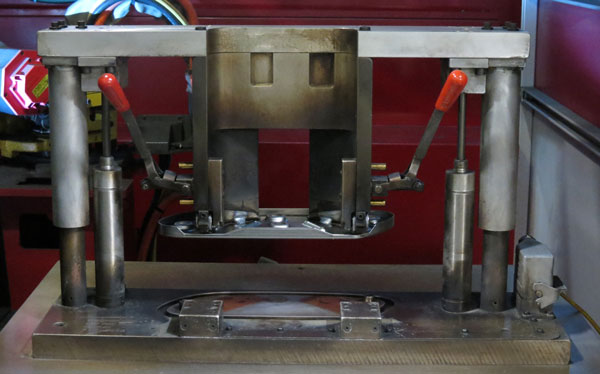

Each footboard required eight “1- inch” welds so Ultra designed and built a customized welding fixture. This established a stable location for the robotic arm to weld more consistently and at a faster rate.

|

And with two robotic welders, CNC Panasonic Robotic Welder and the Genesis Robotic Welder, Ultra can produce two footboards at a time – Decreasing downtimes and increasing production rates. |

A customized functional gauge designed and built at Ultra tests the placement of the welded hinges ensuring the footboard is ready for assembly.

In addition, the Metal Stamping of both footboards was completed at Ultra. Our Value-Added area completed this manufacturing process with visual inspections of the footboards.

Customer Outcome

Production rates were doubled and labor costs were decreased with the introduction of the robotic welder.

Precision and accuracy of the welding improved for a more secure fit onto the motorcycle.

Other Case studies

Providing Innovative Tooling Dies

This project focused on improving the performance and quality of the cutting operation located in this production tooling. This also included an effort to increase accessibility of this cutting component.

Read more →Customizing Parts with Metal Fabrication

Providing high-quality and durable metal components for the manufacturer to support flexible assembly options at the customer’s facility.

Read more →Precision Metal Fabrication Components

Established a metal bending and metal cutting process to produce components for a fan assembly requiring a precision fit to operate as designed.

Read more →Metal Part with Weight Requirements

The total weight of this part and the positioning of its legs are critical to its performance. An automated inspection system was created to verify both of these features are met after metal stamping has been completed.

Read more →