Case Study: Precision Metal Fabrication Components

This Wisconsin-based manufacturer of outdoor power equipment wanted a local supplier to improve responsiveness, reduce shipping costs, and gain more personalized support.

Accurately producing each metal component in this four-piece assembly was essential to ensure a consistent, high-quality fit during operation.

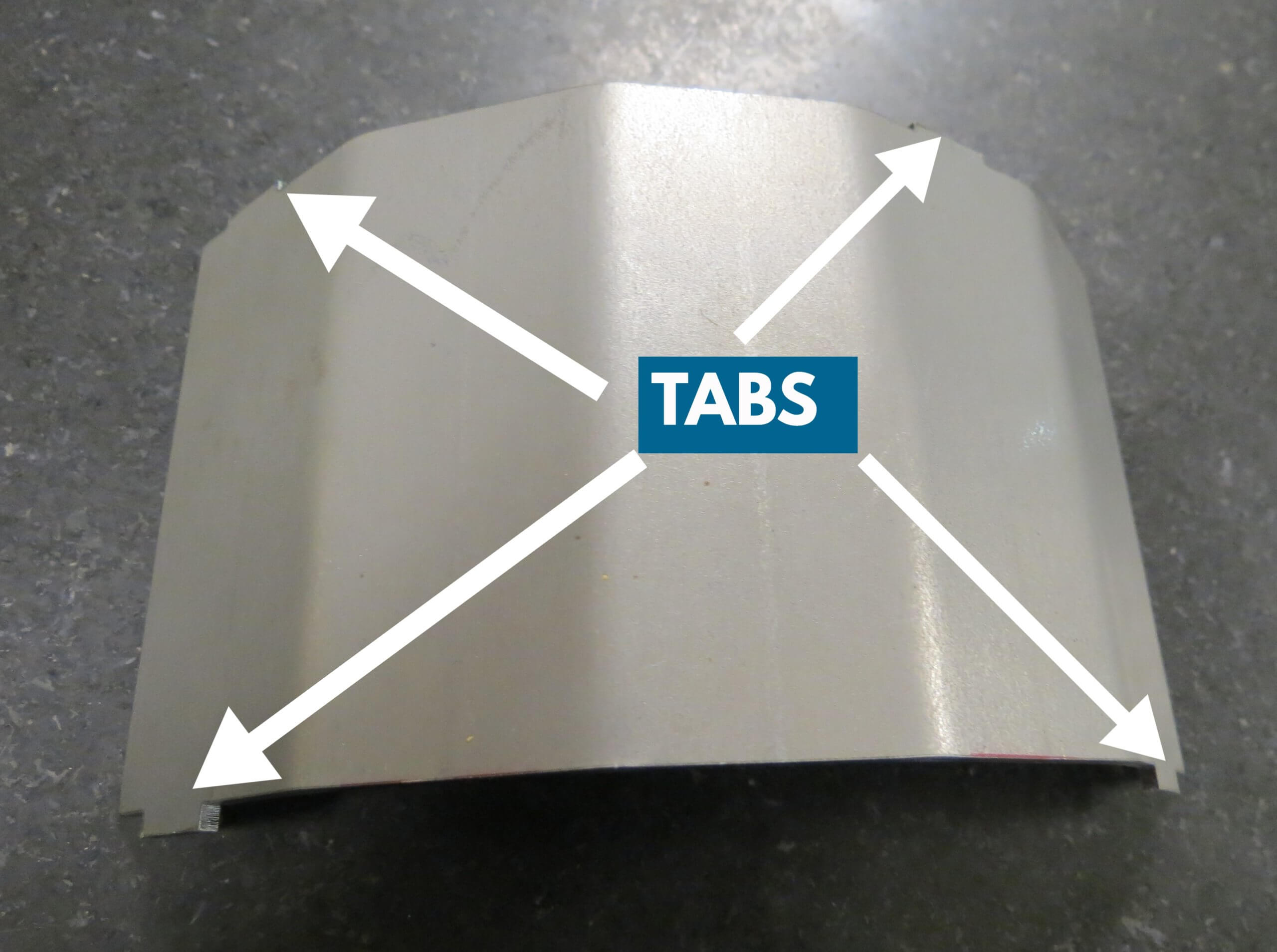

Blade Production

The customer designed the fan blades with four individual bends to improve airflow during operation and to take advantage of standardized press-brake tooling rather than more expensive custom tooling

The blades present two key challenges to manufacture as designed.

1. Managing the overbends and underbends that naturally occur in materials during metal forming.

2. The exact placement and size of the four tabs on each blade. These tabs are critical to successfully align with the slots on the disk.

Utilizing the capabilities of the CNC press brake, our Fabrication Technicians consistently apply their material knowledge and manufacturing experience to match the blade's design print.

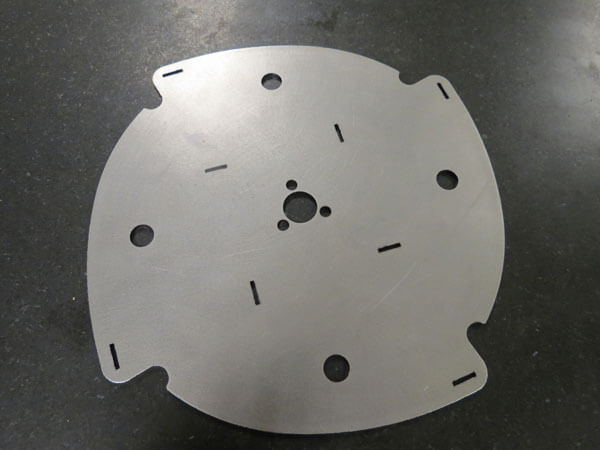

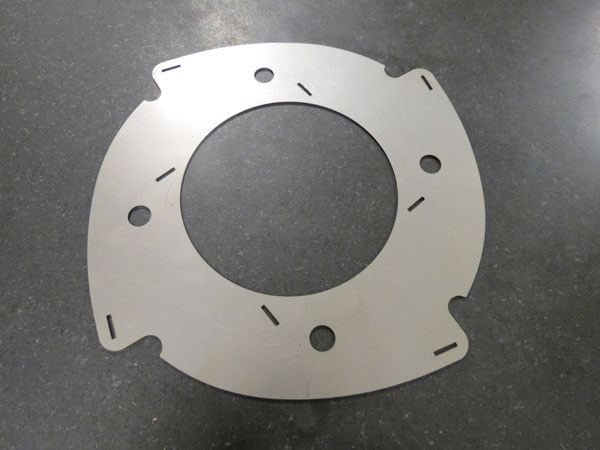

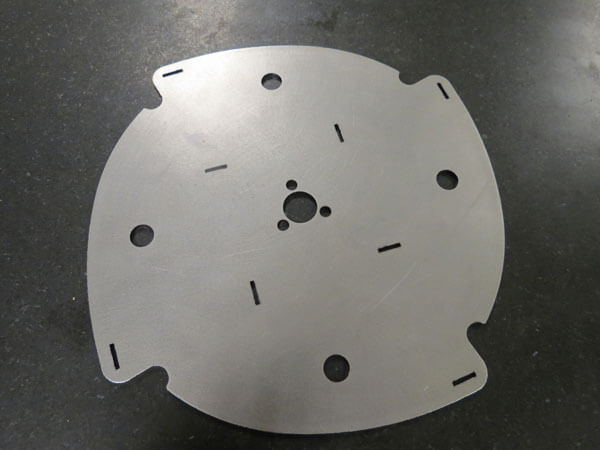

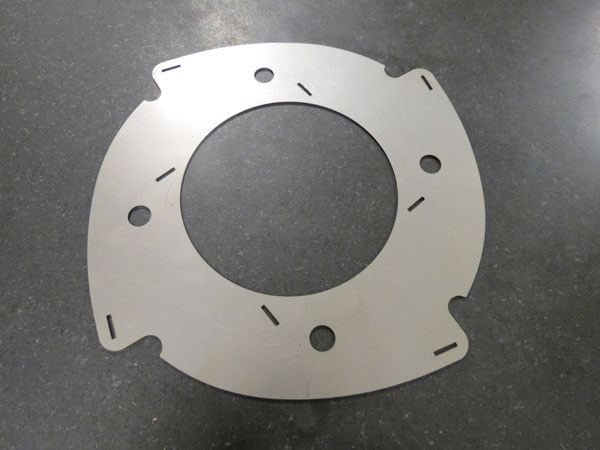

Disk Production

The most critical feature in laser cutting these disks is the slots. Their placement needs to be exact and within a tight tolerance to ensure correct alignment with the blade’s four tabs.

Using Ultra’s prototyping standards, we established the correct fiber-laser programming before final production. We then verify accuracy with regular quality checks, including set-up and in-process inspections, to ensure every blade matches the design print.

Customer Outcome

Ultra’s precision-fabricated metal parts consistently meet the customer’s assembly requirements at their manufacturing facility.

The customer is also utilizing our services to manufacture 14 different metal components for their blade sharpening assembly.

Other Case studies

Forming a Metal Part With the 800-Ton Press

This ramp is manufactured on a progressive die that includes only one forming station to complete that stage of production. A detailed finishing process includes deburring and polishing.

Read more →Comprehensive Die Maintenance Services

Delivering comprehensive die maintenance services to extend tool life and keep the customer’s production running smoothly.

Read more →Providing Innovative Tooling Dies

This project focused on improving the performance and quality of the cutting operation located in this production tooling. This also included an effort to increase accessibility of this cutting component.

Read more →Customizing Parts with Metal Fabrication

Providing high-quality and durable metal components for the manufacturer to support flexible assembly options at the customer’s facility.

Read more →Prototyping to Production

A successful transition from a two-piece welded assembly to one-piece aluminum frame with 21 hardware insertions required the manufacturing expertise of our Die Designers and Toolmakers.

Read more →