Case Study: Reducing Costs with a Progressive Stamping Die

Customer

Motorcycle Manufacturer

Part

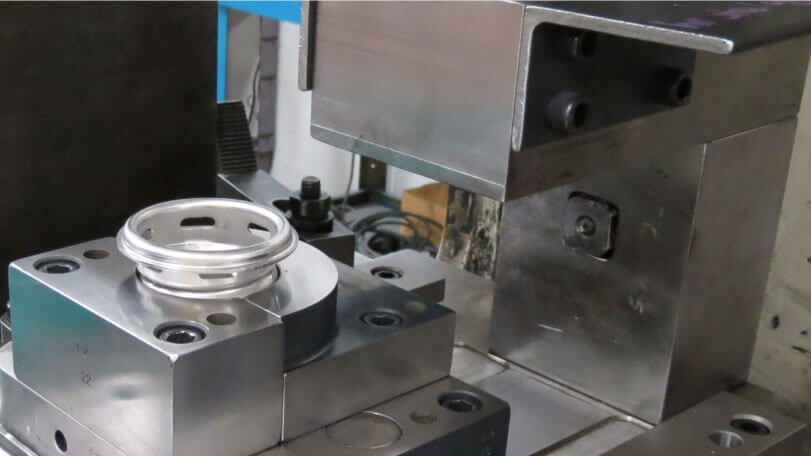

Fuel Filler Cup

Manufacturing Issue

Production costs increased after a splash guard and six drainage slots were added to meet updated safety requirements, rendering the customer’s existing tooling unusable.

Customer’s Goals

Reduce production costs by transitioning to a more efficient, repeatable manufacturing process.

Ensure the new features maintain the overall functionality of the fuel filler cup.

Redesign Process

A progressive stamping die was determined to be significantly more cost‑effective than the customer’s existing hand‑fed process. Ultra designed and built a new multi‑station die to create the part’s overall shape, form internal threads, and pierce the six drainage slots. Two stations formed the internal threads from the inside to eliminate burrs and meet cosmetic requirements. - With Ultra’s 800‑ton press and 168” bed, most operations were consolidated into one tool, reducing time, labor, and secondary operations.

The final operation used a smaller hydraulic press to accurately position and secure the splash guard, further reducing manual labor and improving consistency.

Customer Outcome

Ultra’s customized manufacturing process reduced costs and increased production rates.

The updated fuel filler cup met all required safety and performance standards.

The customer trusts our expertise and services to metal stamp two different sizes of this design for their assembly needs.

Other Case studies

Delivering Cost-Savings for a Metal Stamped Part

By redesigning the manufacturing approach and shifting assembly into a progressive stamping die, Ultra delivered significant cost and efficiency improvements.

Read more →Quality Controlled Manufacturing Process

This manufacturing process uses a blend of Ultra’s in-house capabilities and select outside suppliers. Continuous AQL inspections ensure each metal part is delivered defect-free.

Read more →Achieving Manufacturing Cosmetic Standards

This stainless steel part is metal stamped in our 800-ton press using a 144-inch progressive stamping die that successfully removes sharp edges and cleans the surface areas.

Read more →Improving the Production Process

This customized bracket required six bends and eight holes, demanding a precise fabrication process. Ultra optimized forming, hardware insertion, and inspection to increase production rates and meet design requirements.

Read more →