Case Study: Die Maintenance Services

A security systems manufacturer was finding it difficult to perform scheduled preventative maintenance on its metal stamping dies for two main reasons.

- Decreasing workforce

- Increasing inventory of dies

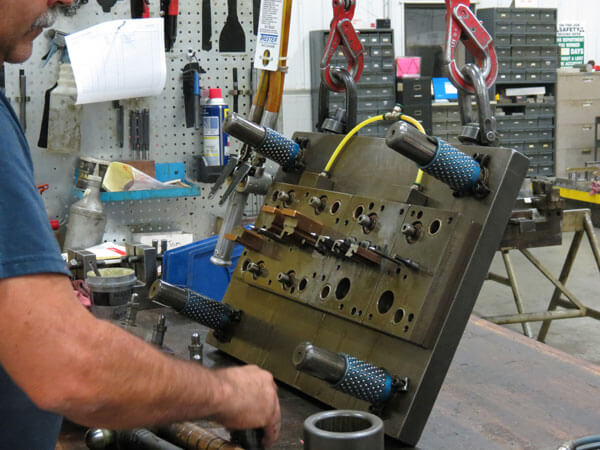

These issues were causing a decline in the precision and quality of service performed on their stamping dies. The customer needed a tool & die partner capable of handling both the volume and variety of their dies—providing consistent preventative maintenance as well as support for unexpected service issues. With more than 50 years of die-building experience, five toolmakers dedicated exclusively to die maintenance, and the resources of a full-service tool room, Ultra was selected to support and service their stamping dies.

Service

Preventative maintenance is scheduled based on a predetermined number of strokes on the stamping die. Once that threshold is reached, the customer notifies Ultra, and we pick up the die at their facility. Ultra’s maintenance program includes both standard services performed on all dies and customized services based on each die’s size and complexity. The services shown below represent only a portion of the work included in our standard die maintenance process.

- Clean the tool

- Inspect all components for wear and damage (cutting, forms, strippers, pilots, etc.)

- Dull components are sharpened and shimmed back to the correct heights.

- Forms are polished.

- Forms and components that are worn or can no longer be repaired to their original state are changed out

- Dies with nitrogen springs are checked for pressures and if needed they are drained and refilled.

Reassembling a stamping die in the correct manner is of critical importance to return to high-quality and consistent production. Clearances are also re-checked to ensure there will be no issues once metal stamping resumes at their manufacturing facility.

The length of the die and the number of components determine the repair time. Standard turnarounds have been set with this customer to keep their production running as scheduled. Modifications can be made when production emergencies arise; such as unexpected breakdowns and rush orders. For example, we were able to return a serviced stamping die back to their manufacturing facility within two days.

Customer Outcome

Ultra set up a service schedule that allows the customer to maintain their production schedule with limited interruption.

Preventative services were no longer being overlooked or intentionally skipped by the customer.

Complete preventative maintenance by Ultra improved the longevity and functionality of their stamping dies.

- Small dies on average takes 8 hours to service.

- Large dies on average takes 20 hours to service.

- These times are based on dies ranging from 24” to 96” in length.

Other Case studies

Forming a Metal Part With the 800-Ton Press

This ramp is manufactured on a progressive die that includes only one forming station to complete that stage of production. A detailed finishing process includes deburring and polishing.

Read more →Delivering Cost-Savings for a Metal Stamped Part

By redesigning the manufacturing approach and shifting assembly into a progressive stamping die, Ultra delivered significant cost and efficiency improvements.

Read more →Achieving Manufacturing Cosmetic Standards

This stainless steel part is metal stamped in our 800-ton press using a 144-inch progressive stamping die that successfully removes sharp edges and cleans the surface areas.

Read more →Improving the Production Process

This customized bracket required six bends and eight holes, demanding a precise fabrication process. Ultra optimized forming, hardware insertion, and inspection to increase production rates and meet design requirements.

Read more →Prototyping to Production

A successful transition from a two-piece welded assembly to one-piece aluminum frame with 21 hardware insertions required the manufacturing expertise of our Die Designers and Toolmakers.

Read more →