Case Study: High-Volume Metal Stamping

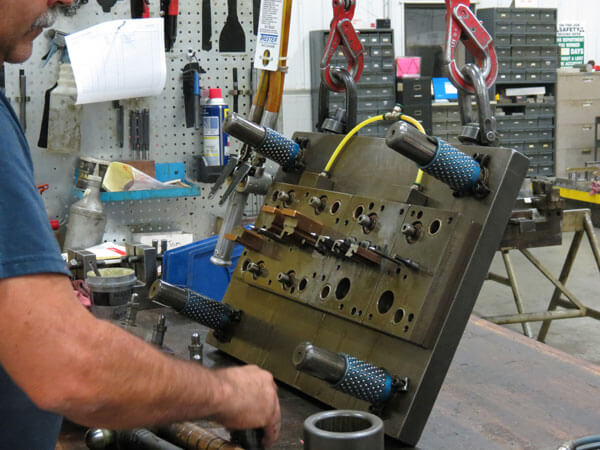

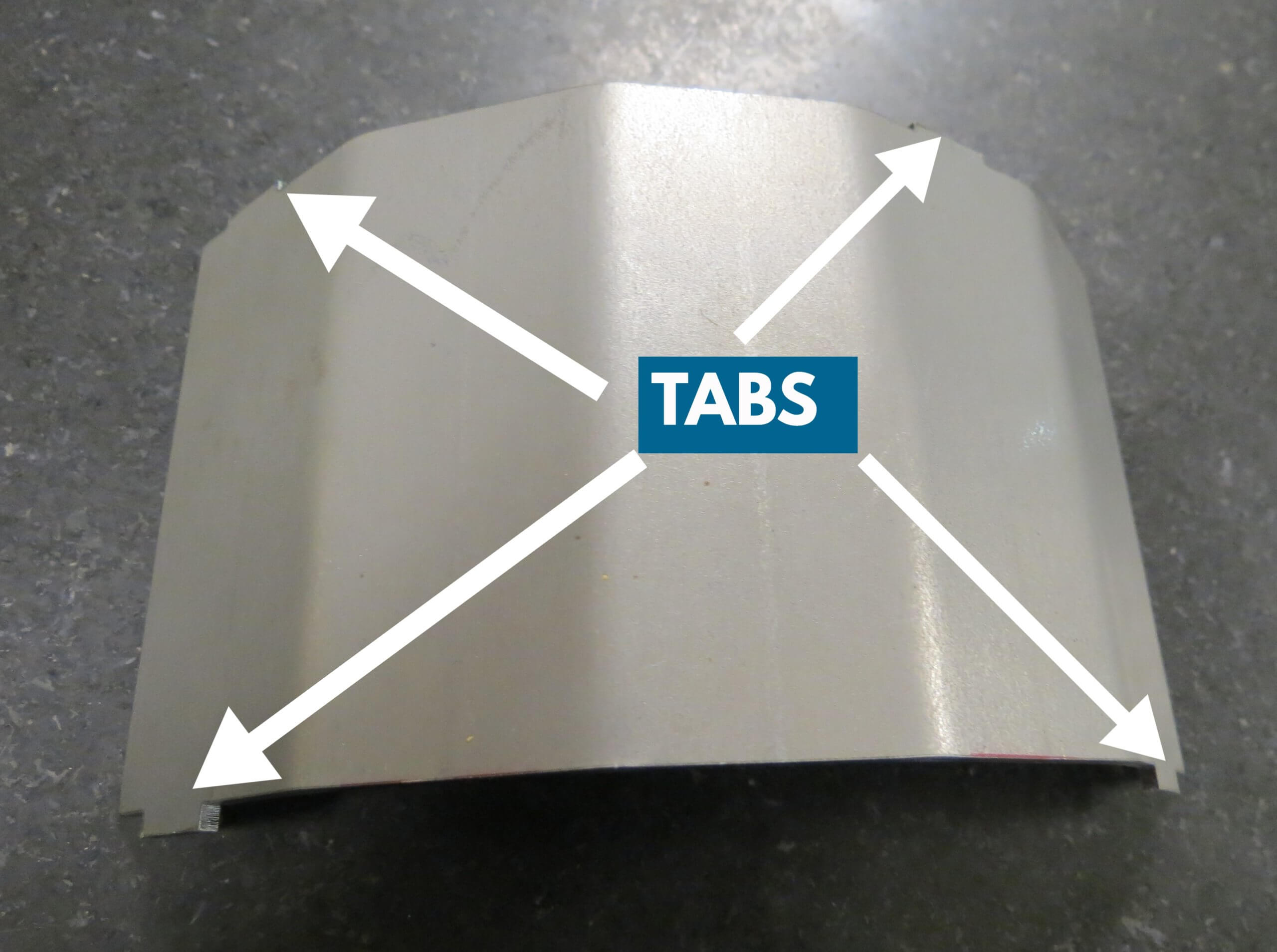

The customer's production needs are 600,000 – 700,00 pieces per year for FIVE different shells having a uniform shape with slight variations in each design.

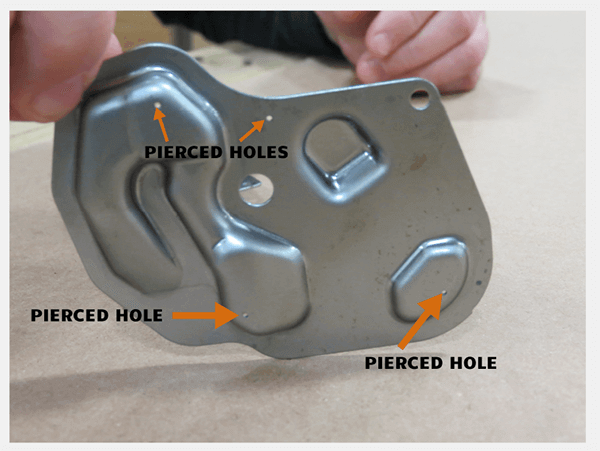

The shells shown to the left are almost identical except for the design and dimensions of their bottom lips. Previously, the customer was utilizing secondary machining to crimp the lip after stamping; and this method was expensive and extended the production time.

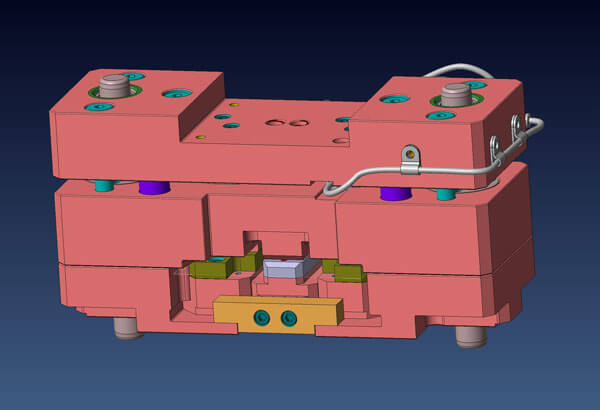

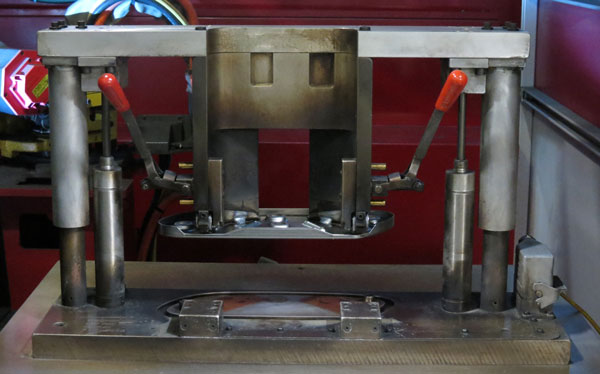

Ultra implemented two key changes to reduce manufacturing costs and improve production time. First, we designed and built the crimping operation directly into the customer’s progressive stamping dies, eliminating the need for secondary machining.

Second, we reduced the customer’s tooling costs by consolidating their progressive dies from five to two. This was possible due to the uniform shape and design of the shells. The final station was designed for easy changeover to one of five custom stations to complete the stamping process

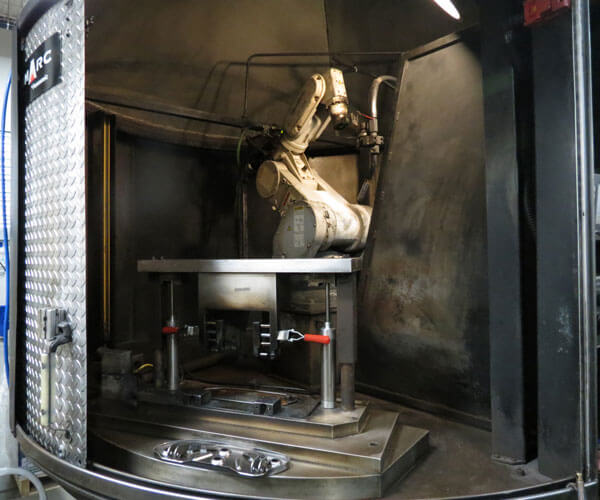

Watch this metal stamping deliver cost-savings.

Other Case studies

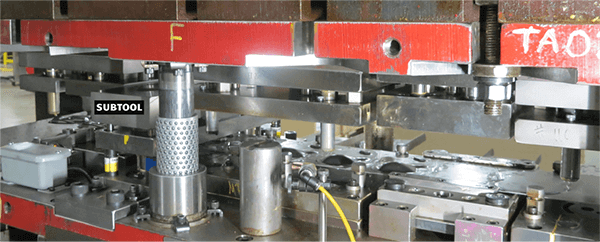

Forming a Metal Part With the 800-Ton Press

This ramp is manufactured on a progressive die that includes only one forming station to complete that stage of production. A detailed finishing process includes deburring and polishing.

Read more →Comprehensive Die Maintenance Services

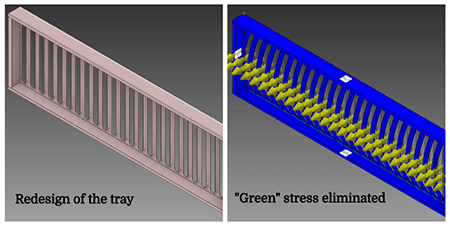

Delivering comprehensive die maintenance services to extend tool life and keep the customer’s production running smoothly.

Read more →Providing Innovative Tooling Dies

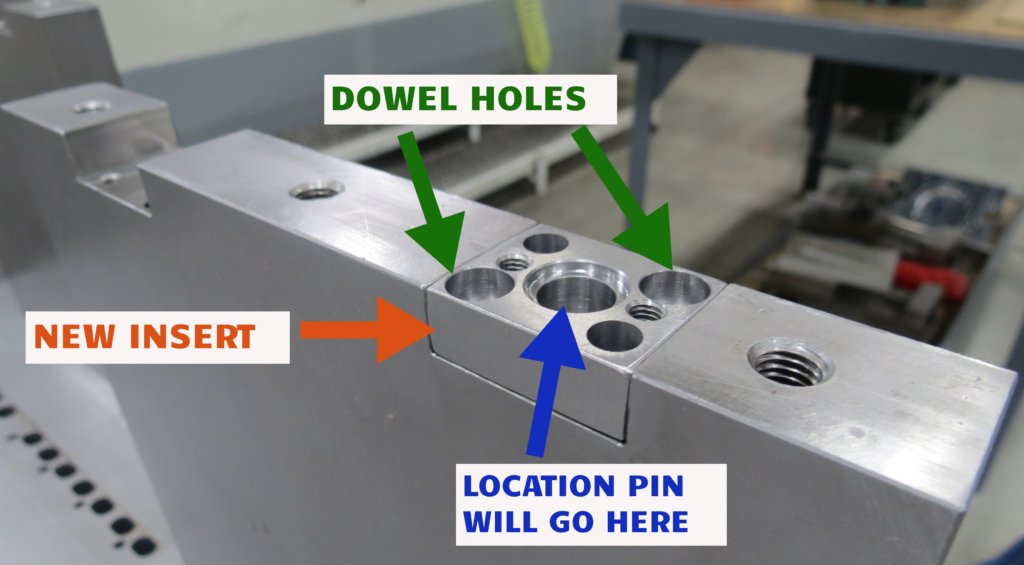

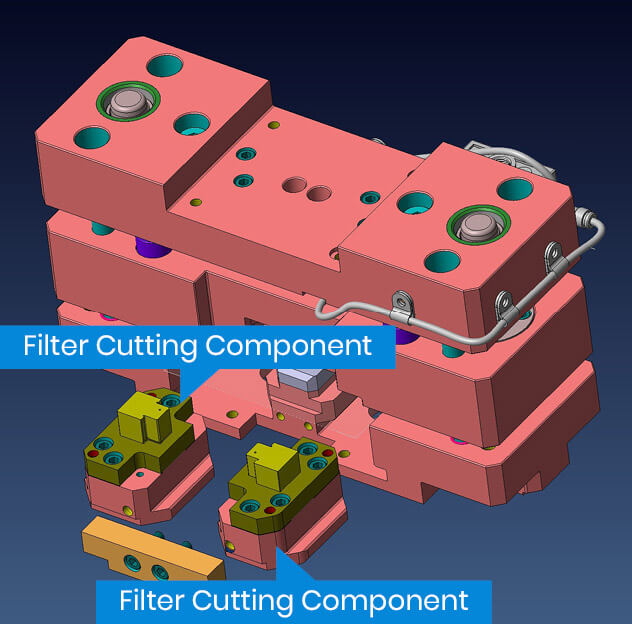

This project focused on improving the performance and quality of the cutting operation located in this production tooling. This also included an effort to increase accessibility of this cutting component.

Read more →Customizing Parts with Metal Fabrication

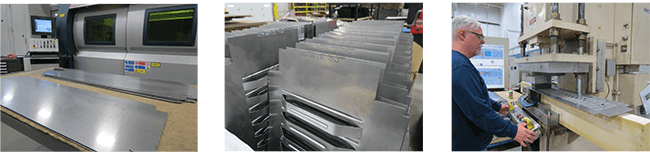

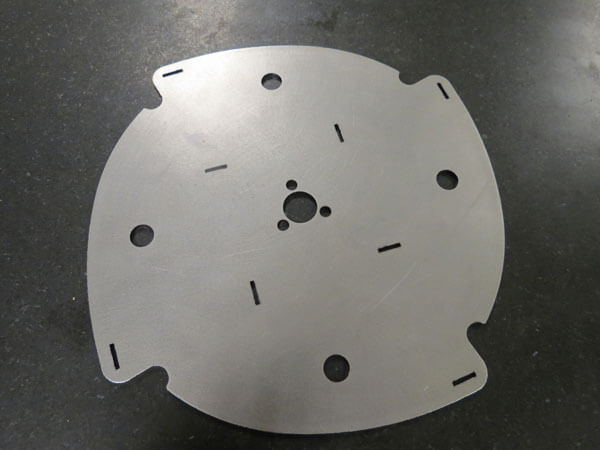

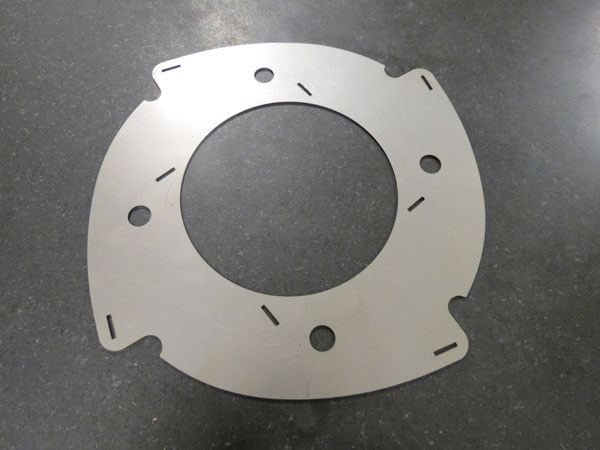

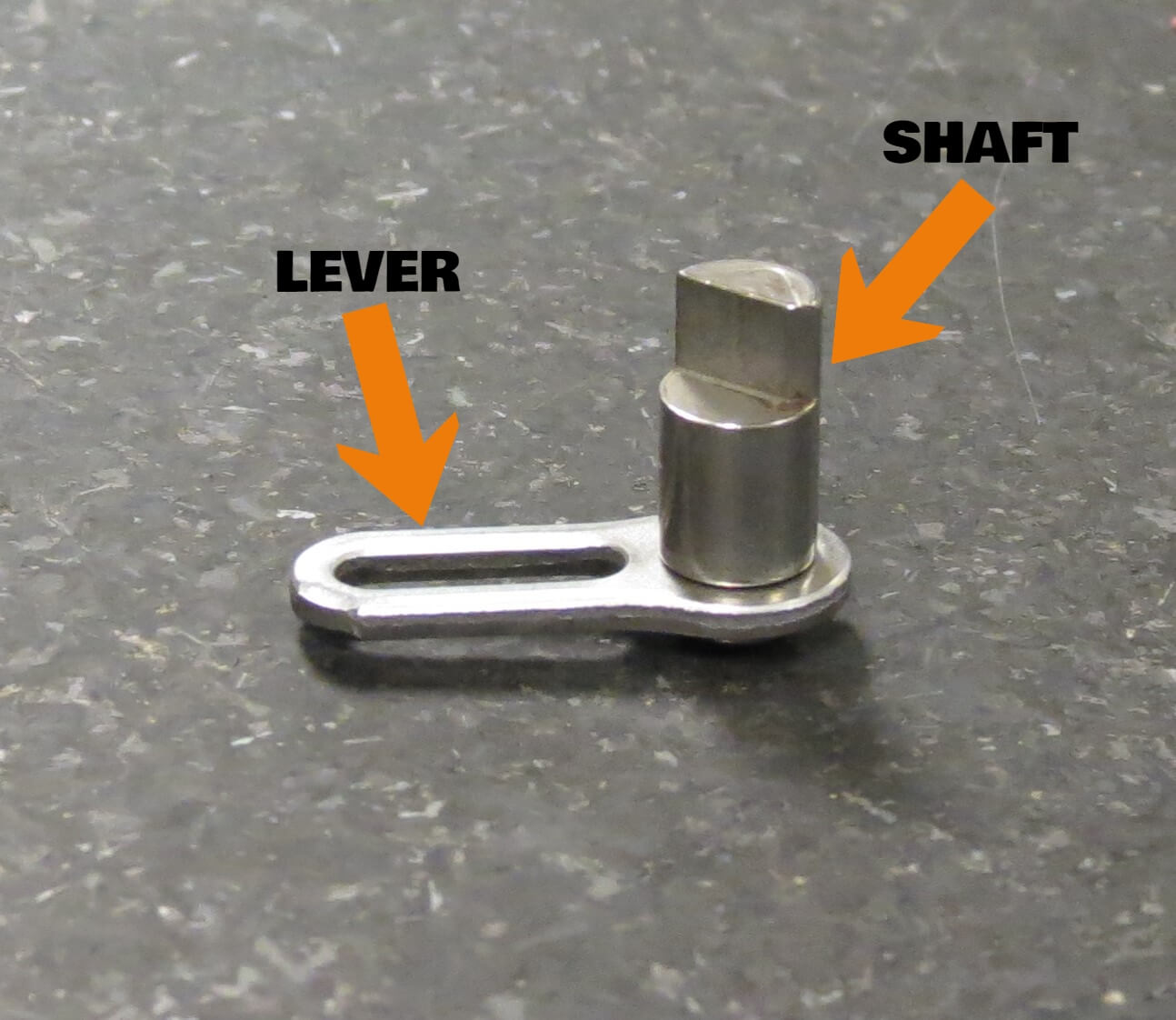

Providing high-quality and durable metal components for the manufacturer to support flexible assembly options at the customer’s facility.

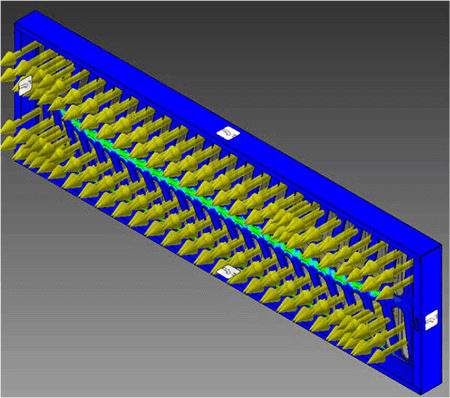

Read more →Precision Metal Fabrication Components

Established a metal bending and metal cutting process to produce components for a fan assembly requiring a precision fit to operate as designed.

Read more →