Applying Metal Forming Expertise to your Manufacturing Goals.

Quality. Repeatability. Innovation

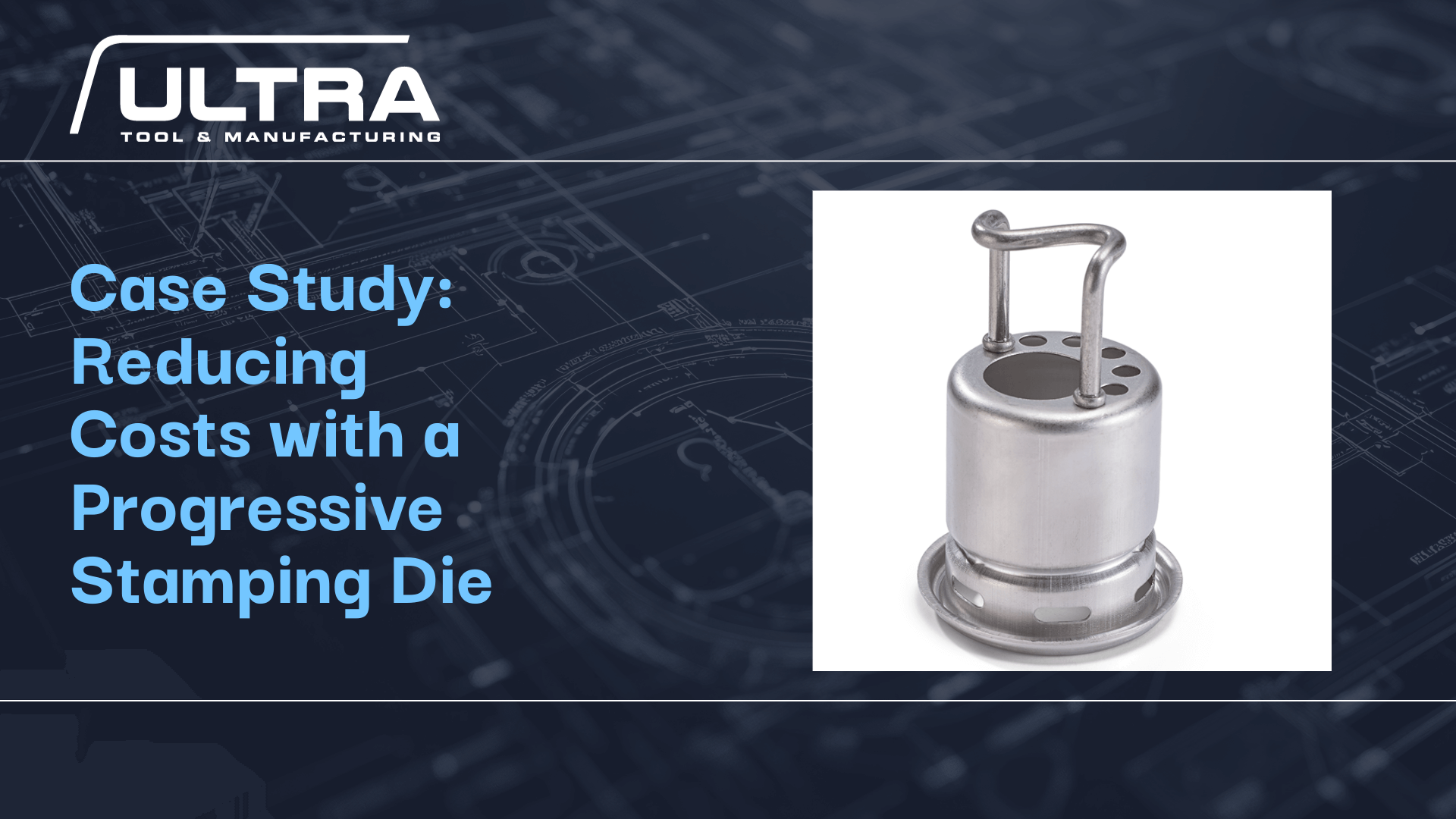

Reducing Costs with a Progressive Stamping Die

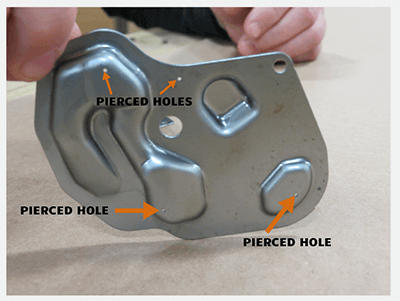

Safety‑driven design changes—including a splash guard and six drainage slots—made the customer’s existing tooling unusable and increased production costs. Ultra engineered a new progressive stamping die that reduced cost per part while ensuring all added features maintained the full functionality of the fuel filler cup.

Read more

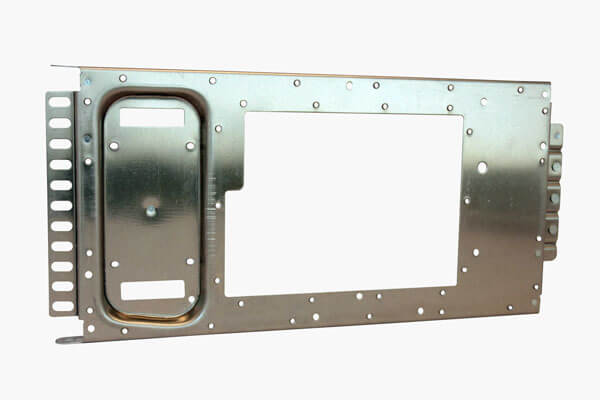

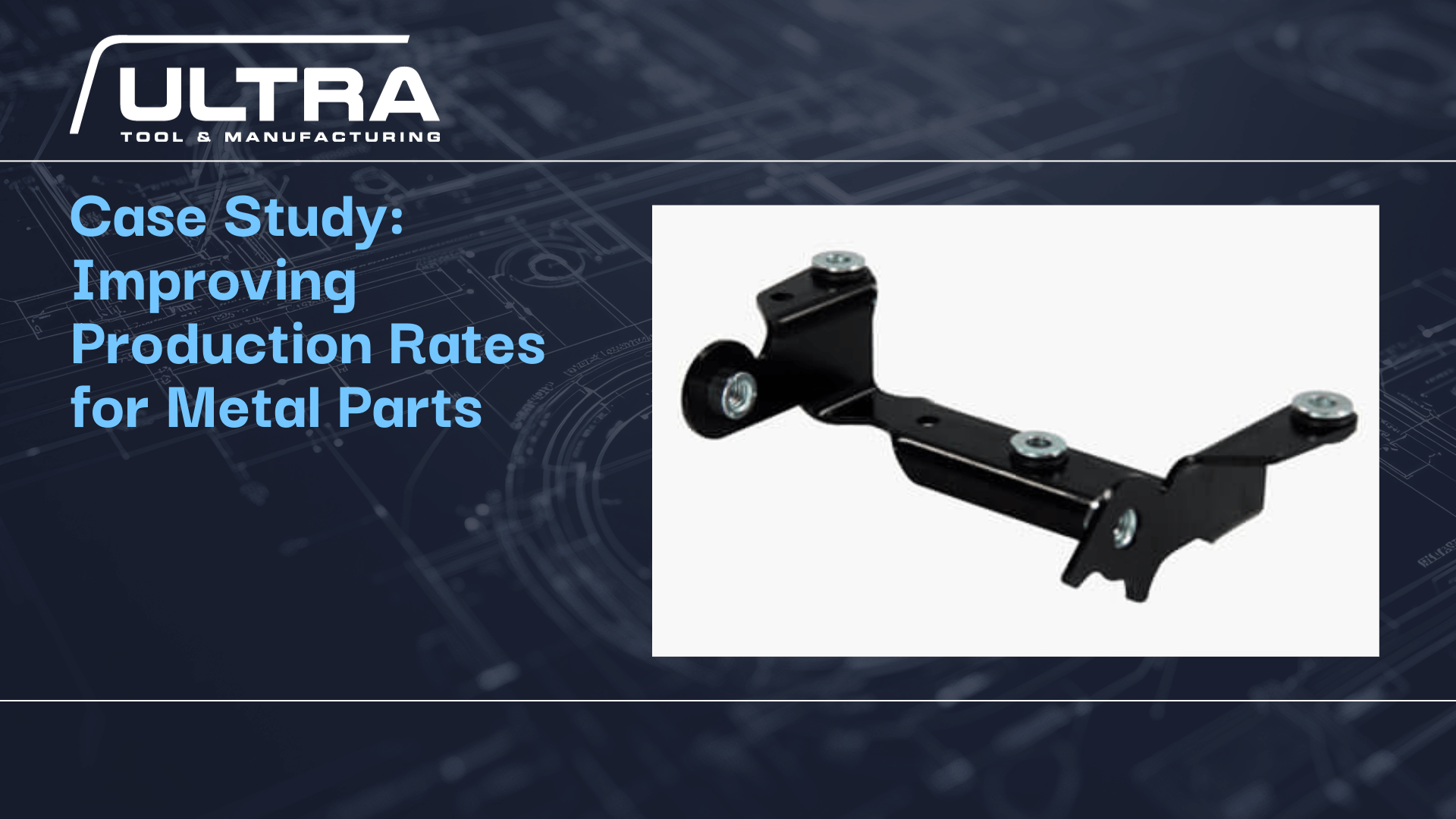

Outdoor Power Equipment Metal Stamping Case Study

Manufacturer of Rotary Lawn Mower Blade Sharpeners and Balancers for the Outdoor Power Equipment Industry

A recommendation from their previous supplier brought Outdoor Power Equipment Manufacturer’s leaders, Gerd & Erik Bauer, to Ultra’s front doors to continue production of their lawn mower blade sharpener.

Read more